The conception and subsequent production of gas filling plants are by no means a simple business. There are a lot of ‘low-level’ usages (single cylinder filling) for which a standard-solution is enough, but larger and primarily gas business related companies are still looking for a ‘tailor-made’ or customised solution.

But what is the best way to describe the typical development of a gas filling plant? Here I will discuss a current project which we completed some months ago at Filltech, involving the development of an intelligent filling system for carbon dioxide (CO fire extinguisher cylinders. Due to its many safety aspects, this project was an interesting and enormous challenge for all departments at Filltech.

Typically I have to start this by talking about a well-functioning project management which controls this kind of venture. In Germany there was a specific DIN standard for this; DIN is about the fundamentals, processes, process models, methods, data and data models of a project’s management. This project description ends in a breakdown of all of its actions, milestones and time limits. And at the end of the day, the number of Gantt diagrams and roadmaps is so large that you could use them all to decorate the offices that you and your colleagues work in.

Christian Peine, CIO at Filltech GmbH, once rightly pointed out, “A linear work breakdown structure looks like uncooked spaghetti. We at Filltech believe that it is important to see product management more as a plate with well-cooked spaghetti, with meatballs. This symbolic picture shows the meatballs as milestones close together, but the path between them is almost not linear.”

What Peine means becomes obvious if you have ever seen Filltech in action. Of course we know all the important steps of project management like project identification, quotation, contract negotiations, design, procurement, installation, commissioning, warranty and on-site service very well - these parts are known variables to us and are of course relevant in the chronological sequence. Due to many successful projects in recent years, our current understanding of planning is pretty much developed - but we realise that projects are made of people and thus, certain group dynamics are always a part of meeting the optimal project requirements.

The procedures in the development of fillings systems are also due to the internal structure of Filltech as a company. Some areas of decisive importance (sales, construction and IT) are headed by the three members of the Filltech management, which are closely related as father and sons. The situation of being together so closely is a guarantor for the steady cross-department communication and immediate information exchange of the Peine-Family in the case of unforeseen needs and decision-making.

At the time of project initiation, a thorough appraisal and analysis of the customer wishes and needs is fundamental. These problems could be simple and trivial like trying to get gas from one point to another. Or it could be more challenging. For example, we have to check if an existing plant can be modified or upgraded, or if the plant has to be replaced and completely rebuilt. Reasons to go for a new filling plant are very often an optimisation of processes, with a reduction of costs and an improvement to the quality.

After the first customer meeting with our technical sales team we have the basic information and can determine the feasibility. Information about the cylinders, the type and composition of the gas, and the required filling procedure are important to get an initial overview of the range of functions and the design of the filling plant. Additionally to the feasibility, we also check the commercial usefulness of the development of a plant to optimise the return of investment (ROI). Especially with regards to the sustainable future development of the customer, we have to evaluate if an extended standard plant or a tailor-made version of a filling plant is a better option for the needs of the customer. The challenge is: the customer often knows what he wants, but not necessarily what he actually needs.

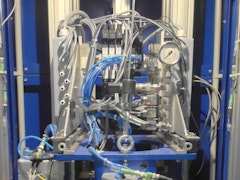

Within the analysis and a design study of a new filling system for CO2 fire extinguisher cylinders, we realised that our customer was carrying out all of the filling processes - including cylinder preparation and handling - manually. The problem of the sequence of these processes was recognised easily: all the filling material was scattered, and in every process there was material storage unused - essentially ‘dead capital’. An intelligent, fully automated plant from Filltech fulfilled all of these processes in one single process, creating a single workflow where all steps move cleanly into another. More ‘single-piece flow’ than ‘batch and queue’ production.

Design and development

Starting from the feasibility, you can then discuss some initial price expectations with the customer. In further discussions, these expectations are adjusted following the ongoing design process of the filling plant; there are naturally differences in the type and duration of plant development between a plant for capsules (filled with xenon and welded under pressure), an industrial plant for the simultaneous filling of litre cylinders, or a plant for refilling road tankers.

Once the general information is established and the future design and range of functions are clarified, the next step is the requirement solving. In this step, different specialised teams with their respective knowledge and experiences are employed. Now, the group dynamics begin. The pricing and evaluation of the development time of an individual tailor-made filling plant has to be judged by specialists; the mechanical processes must be considered before the proper filling process starts and after it ends; complicated functions such as the detection of different information of the track and trace system must be evaluated; at the construction level engineering drawings of required plant components, different plant sections and of course of the whole filling plant need to be made; and the P&ID, which shows flow and processes sheets and diagrams, must also be addressed. At an IT level, there is, on the one hand, the PLC (Programmable Logic Controller) which controls and regulates the plant, and on the other hand there is the computer-based system which monitors the plant and prepares data to visualise it.

At this point I would like to stretch the curve to the project management again; Filltech project management includes, among other things:

- Share-point document management system

- Recording of all data of the cost structure

- A centralised digital drawing administration archiving

- A central intelligent code management system (repository)

It is always interesting to see all of the different details and components of a filling plant arise in the development process (aside of the customer’s wish). It is not rare that customers, at the latest during commissioning, are very surprised and impressed by what a creative mind can do. This not only applies to the whole recording of all requirements along the development process of the filling plant, it could also mean the development of system programmes for integration with the custome’s ERP system - or the impressive data visualisation shown on screens throughout the plant and in the plant manager’s office.